TECHNICAL SPECIFICATION

Model | DX05A-200 |

Total Power | 6.0KW |

Input Power | 380V 50Hz 3Phase |

Motor Power | 3.0KW * 2 |

Motor Speed | 2840 r/min |

Air Pressure | 0.6-0.8 MPa |

Diameter of Vertical Blade | Φ500mm×φ30mm |

Diameter of Flat Blades | Φ160 *2 pc Φ200 *1 pc |

Cutting Angles | 45°, 90° |

Diameter of Main Shaft | 32mm |

Worktable Journey | 750 mm |

Worktable Size | 360*235 mm |

Overall Dimension | 1400*1100*1500 mm |

Gross Weight | 400 KGS |

MAIN FEATURES

• Used for milling the end faces of the middle mullion of aluminum doors and windows, and UPVC doors and windows.

• Equipped with two 3kW spindle motors, the first motor is equipped with two or more horizontal saw blades; the second motor is equipped with a vertical saw blade, which can cut and strengthen mullion.

• The widened workbench can mill 2-3 aluminum materials at the same time, which is more efficient than ordinary small end milling.

• Small size, powerful functions, and high cost performance.

• Low-voltage electrical appliances and buttons are made by Schneider, the switch power supply is made by Taiwan Mean Well, and the solenoid valve is made by AirTAC, which is stable and safe.

DETAILS OF DX05A-200 UPVC END MILLING MACHINE

Vertical saw blade for machining reinforced muntins and frame-sash flush systems.

Horizontal blades of End Milling Machine

Linear square guide

Finished product of End Milling Machine of Aluminum & UPVC Window Door

ABOUT BLUETEK

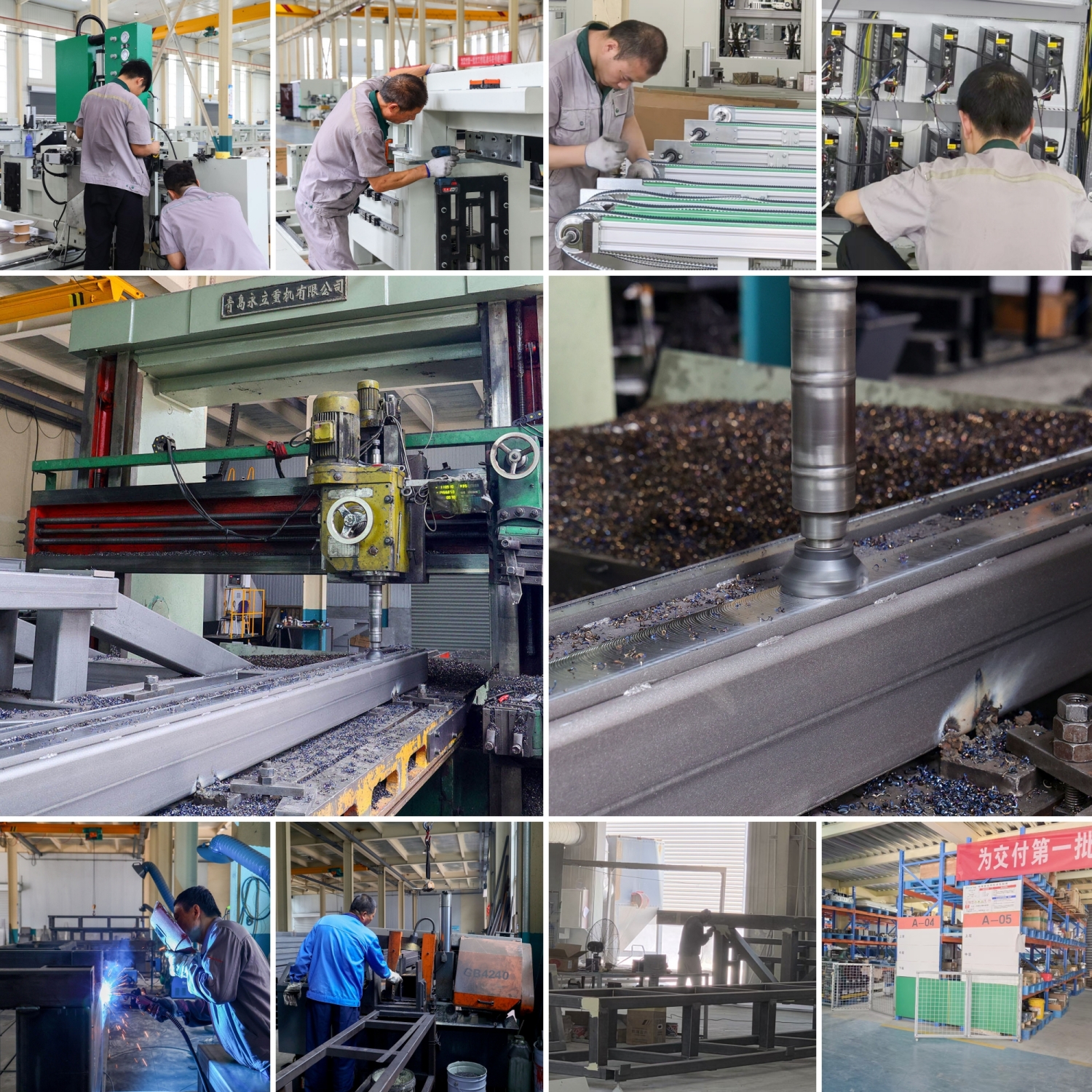

BLUETEK is located in Jinan, Shandong, and have been specialized in mid-to-high-end aluminum door and window manufacturing machines, aluminum curtain wall manufacturing machines, PVC door and window manufacturing machines, as well as industrial aluminum processing equipment and solutions for 20 years.

Our company currently has three modern workshops with a total area of 18,000 square meters, with its own machining, sheet metal processing, and spraying. The total number of employees is more than 100, with a research and development team of more than a dozen people.

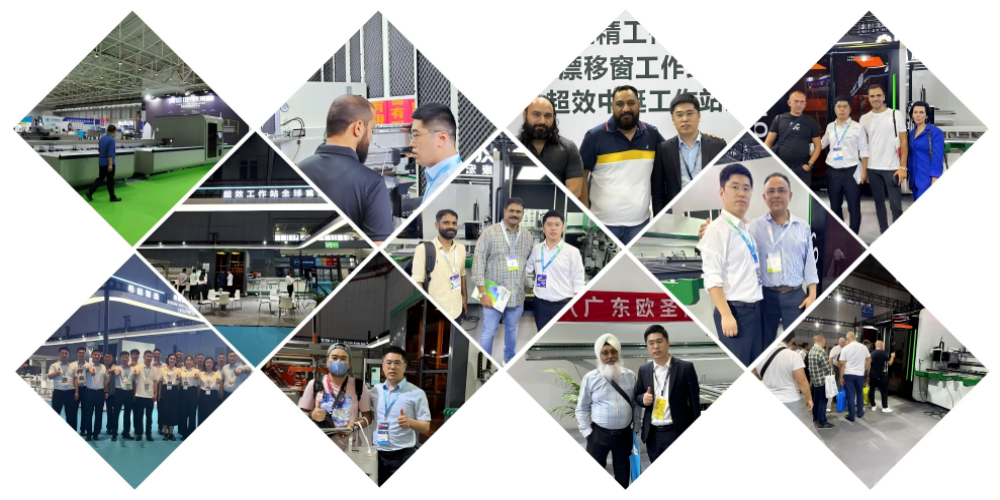

Professional exhibitions at home and abroad

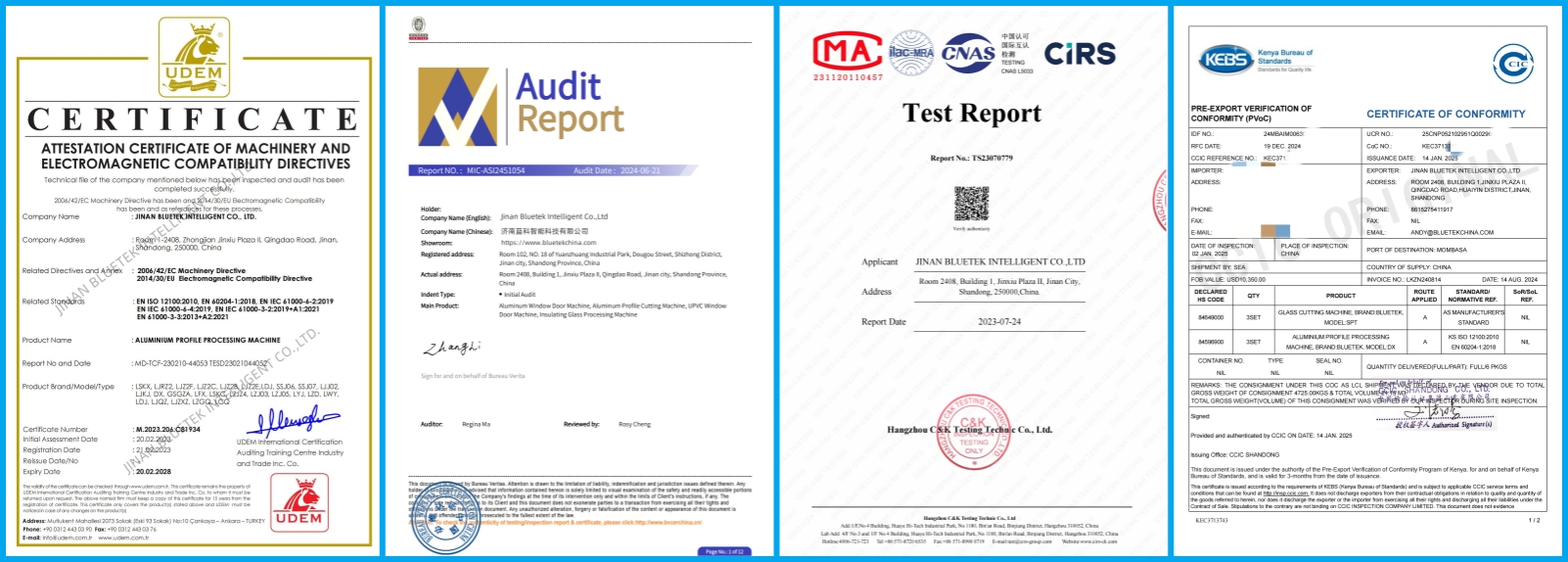

Our products have passed European CE certification, BV certification, CNAS test report, etc., ensuring the safety of the products.

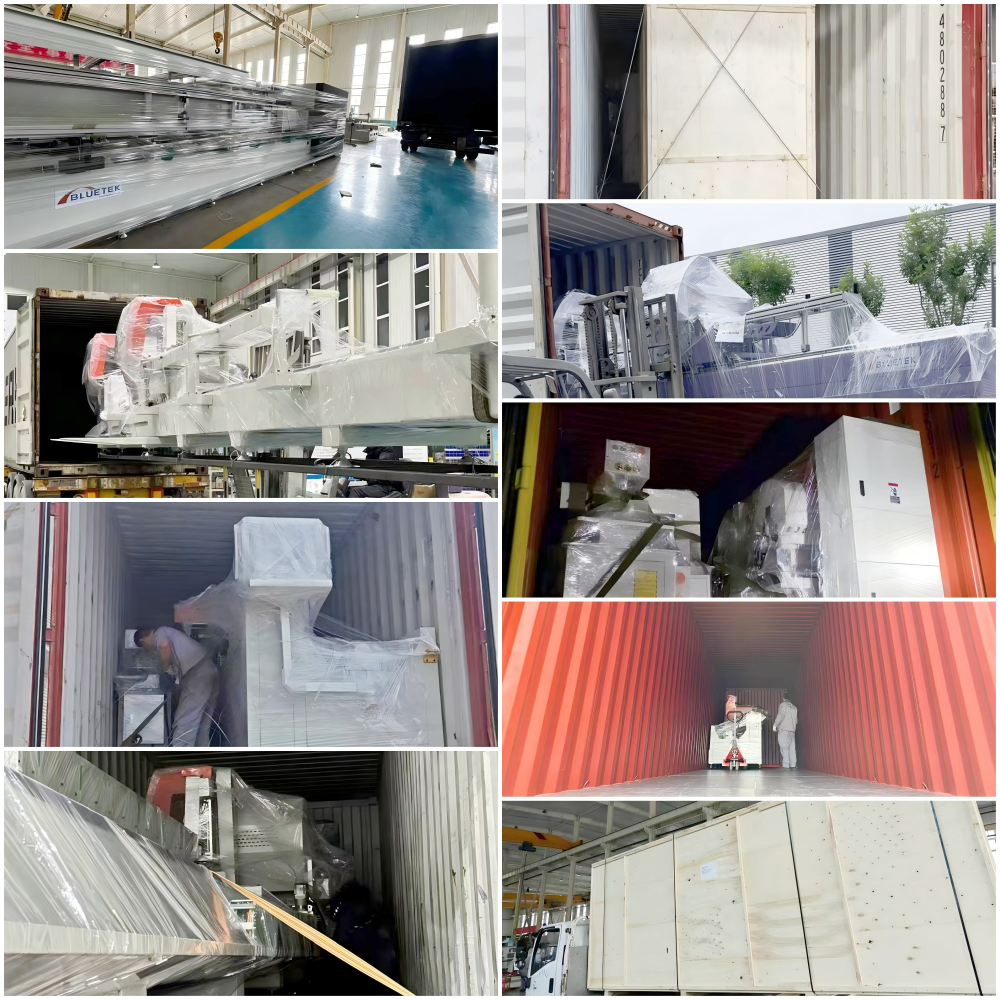

Transportation mode: By sea, rail, land

Loading mode: FCL, LCL

Packing: plastic waterproof film + plywood box