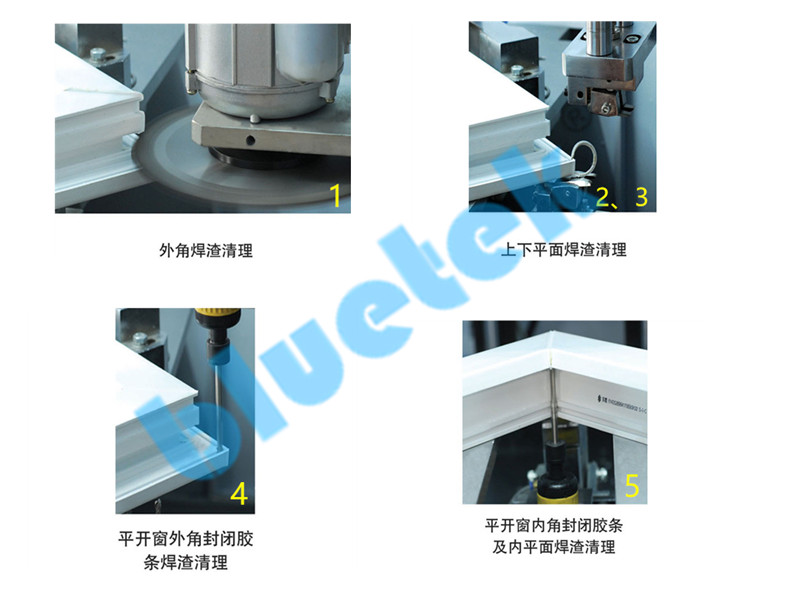

5 TOOLS PVC WINDOW CNC CORNER CLEANING MACHINE

MAIN FEATURES

• 5 Tools PVC Window CNC Corner Cleaning Machine can complete the all-round cleaning of the external corner, the upper and lower sides welding seams, the inner corner inner plane welding seam, the sealing tape groove and the inner plane welding seam.

• The equipment adopts Schneider Servo System, man-machine interface LCD touch display

screen; saw blade motor adopts spindle motor

• The feed of the machine head adopts high-precision square rail movement range,

which effectively guarantees the accuracy of the machine

• According to different profiles, 100 kinds of corner cleaning programs can be set and

stored, which have the advantages of complete functions, simple operation,

fast speed, high precision, high efficiency, and high degree of automation.

TECHNICAL SPECIFICATION OF PVC WINDOW CNC CORNER CLEANING MACHINE

Power Supply | 380V 50Hz |

Input Power | 3.5 (Kw) |

Air Pressure | 0.5~0.8(MPa) |

Process Height | 120 (mm) |

Process Width | 120 (mm) |

Groove Width | 3 (mm) |

Groove Depth | 0.3 (mm) |

Spindle Speed | 2800r/min |

Weight | 700(kg) |

Dimension Size | 1300×1100×1800(mm) |

What machines do you need to produce PVC window door ?

1.PVC WINDOW DOOR CUTTING SAW

There are many kinds of PVC cutting saws, double head cutting saw, single head cutting saw, CNC full cutting saw, semi automatic cutting saw. customer can choose the suitable cutting saw based on budget. According our experience LJZ2-450x3700 and SJZ2-350x3500 are most popular for foreign countries. If need higher degree of automation , SSJ07-CNC-450x3600 CNC double mitre cutting saw is best in China.

2. GLAZING BEAD CUTTING SAW

It's normal type is enough for most customers , even it has CNC type glazing bead cutting saw. It's worktable can adjust height to chamfer.

3. END MILLING MACHINE

It is used for cutting /milling window mullion end-face , so that the mullion end can match and joint with crossbeam. The cutter should be customized for different mullion profiles. It can process aluminium window also.

4. COPY ROUTING MACHINE WITH TRIPLE DRILLING

This machine not only can mill holes and slot for hardware , but also can drill triple holes for lock.

5. WATER SLOT MILLING MACHINE 2/3 AXIS

It can mill drain holes for 3 directions, finishing by one time.

6. SCREW DRILLING FASTENING MACHINE

We have single / two / four/ head screw drilling machine and CNC automatic screw drilling machine. Add a steel lining to the cavity of the PVC profile and fix with a screw fastening machine to improve the strength of PVC doors and windows.

7. FOUR HEAD PVC WINDOW WELDING MACHINE

PVC window welding machine is the MOST IMPORTANT in all these machines. It not only determines the production output of PVC doors and windows, but also determines the quality and aesthetics.

CNC 4 Corner Welding Machine and Four Head Welding Machine are good for large factory ; Three Head PVC Window Welding Machine , Double head Welding Machine and Single Head Welding Machine are suitable for middle and small factory.UPVC Window Making Machine Best Price in India.

Now PVC Window Seamless Welding Machine ( Or PVC Windows Single Side Seamless Welding Machine) is more and more popular. After welding window it can cut welding slag at same time, window corner is more beautiful and corner strength is also high.

The best choice is BLUETEK brand Double Head UPVC window seamless welding machine , We have mastered the best seamless welding technology, which can bring customers better products and increase selling points.

8. PVC WINDOW CNC CORNER CLEANING MACHINE

We have CNC corner cleaning machine with 3 tools . 5 tools or 6 tools, also have Semi automatic corner cleaning machine as a economical choice, and portable corner cleaning machine is also available.

9. PVC WINDOW ARC BENDING MACHINE

It is necessary machine to produce arc window . We recommend electric heating type , not oil heating.