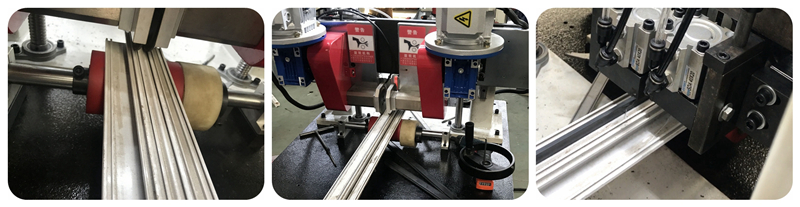

GKCJ-01 Thermal Insulating Aluminium Profile Knurling and Inserting Machine, the round rollers roll teeth on the inner notches of the thermal insulation strips, Increasing the friction between the thermal insulation strips and the aluminum profile, the heat insulation strip can be tightly embedded in the inner notch, and the strength of the heat insulation aluminum is improved.

MAIN FEATURES

1. The two rollers are perpendicular to the worktable, and the distance and the depth of the knurling rollers can be adjusted, which is suitable for the processing and compounding of different broken bridge thermal insulation aluminum profiles.

2. The lifting of the roller is controlled by the electronic control system. When replacing the aluminum profiles, manual adjustment is not required, which saves time.

3. The special lower roller can be adjusted up and down, left and right, for fixing and processing special shaped aluminum materials.

4. The precision screw and electrical components ensure the stability of the threading and the processing speed.

5. This Thermal Insulating Aluminium Profile Knurling and Inserting Machine can realize Knurling, thermal insulating strip inserting, protect film laminating three functions. Reduce investment costs and increase production speed for customers .

TECHNICAL SPECIFICATION

| Name | Thermal Insulating Aluminium Profile Knurling Machine |

| Model | GKCJ-01 |

| Power Supply | Customize |

| Input Power | 1.5KW |

| Diameter of Knurling Roller | 80mm |

| Work Speed | 0~120M /min |

| Process Size of Aluminium | 350x250mm |

| Distance between knurling rollers | 6mm ~150mm |

| Overall Dimension | 1400x1000x1500mm |

| Weight | 720 KGS |