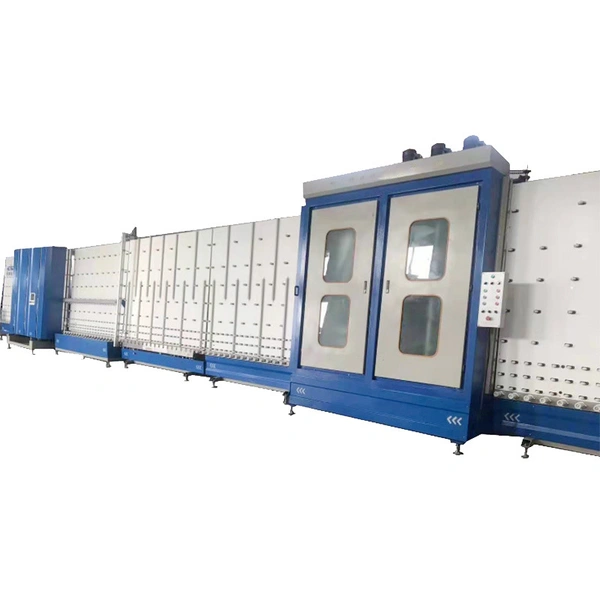

CHINA FACTORY PRICE DOUBLE GLAZING GLASS MAKING MACHINE

AUTOMATIC VERTICAL DOUBLE GLAZING GLASS PRODUCTION LINE

MAIN FEATURES

1. Double glazing glass making machine has two sets of glass assemble systems : Outside assemble and Inside assemble.

2. The whole process adopts PLC control system, touch screen with man-machine interface.

3. Automatic identification of coated glass and LOW-E glass.

4. Using special vacuum generator and suction cup, the glass suction effect is better.

5. It can produce two-layer insulating glass, three-layer insulating glass, and unequal side insulating glass.

6. The display screen can display the running status and fault prompt of each part, and the operator can find it in time.

7. The glass pressing adopts the hydraulic station to drive the rack and pinion, and the glass transmission adopts the frequency conversion speed control device.

8. Optional: Inert gas filling function of Double glazing glass making machine.

9. Processing glass length can be customized.

TECH PARAMETERS

Name | |

Model | LBP2000A |

Power Supply | 110V/ 220v/380V |

Input Power | 33 (Kw) |

Min.Glass Size | 300x500 (mm) |

Max.Glass Size | 2000x3000 (mm) |

Thickness of Glass Sheet | 3~12(mm) |

Thickness of Insulated Glass | 12~40(mm) |

Glass Washing Speed | 3~12M/min |

Working Speed | 3~50M/min |

Overall Dimension | 20000×3000×3100(mm) |

PLC | Omron, Japan / SIEMENS, Germany |

Frequency Converter | Omron, Japan / SIEMENS, Germany |

Servo Motor | KINCO, China Top Brand |

Touch Screen | KINCO, China Top Brand |

Low-voltage electrical appliances | Schneider , France |

ABOUT US

BLUETEK is professional double glazing glass making machine factory from China.

Our company is founded in 2005, is a well-known high-tech private enterprise engaged in Industrial Aluminium Processing Machine , Aluminium Window Door Manufacturing Machine, PVC Window Door Manufacturing Machine, Insulating Glass Processing Machine.

DOUBLE GLAZING GLASS MAKING MACHINE INCLUDING :

1. Vertical Double Glazing Glass Production Line

2. Aluminium Spacer Bar Bending Machine

3. Desiccant Filling Machine

4. Butyl Sealant Coating Machine

5. Two Component Silicone Sealant Extruder

6. Rotating Table

7. Glass Cutting Machine

8. Insulating Glass Unloading Machine