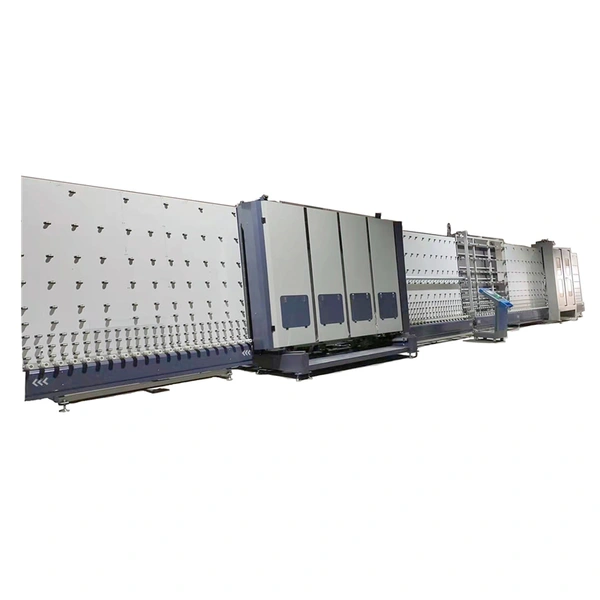

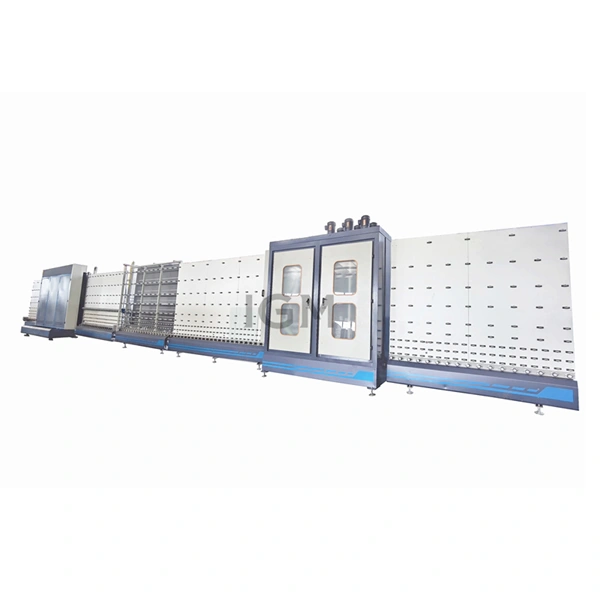

INSULATING GLASS PRODUCTION MACHINE LINE WITH GAS FILLING

MAIN FEATURES

• Insulating Glass Production Machine Line whole process is controlled by PLC and frequency conversion. If no glass enters, the equipment automatically stops running, reducing energy consumption.

• Double glass, triple glass, large and small pieces, special-shaped hollow glass processing function.

• Automatic detection device for glass thickness, length and height.

• The feed section is equipped with a contact coating detection device, which is stable and reliable.

• High-power (18.5KW), high-pressure fan, stainless steel air knife, fast drying speed.

• The fan has a damper, intermittent no-load operation without glass, reduces energy consumption, and has an automatic sleep function.

• 03/04 Cleaning output section and the aluminum frame positioning section can store two small glasses to improve production efficiency.

• Section 04 has the function of picking and placing glass at will.

• Aluminum frame positioning is made of aluminum alloy profile, equipped with position indicator, easy to adjust the glue depth.

• The outside of the board is hydraulically controlled, and the operation is stable and reliable.

• The pressing of the flat pressing section of the combined sheet adopts servo pressing, and the pressing torque is automatically calculated according to the size of the glass to ensure that the glass is pressed evenly and not broken.

• There are 48 adjustment devices for the front pressing plate of the plate pressing section to ensure the flat surface of the plate. The pressing is guided by a linear square rail.

• The large and small pieces on the four sides are controlled by servo motors, with a width of 100mm and a vertical direction of 50mm.

• The inflatable function in the board adopts the down-charging method, which is fast inflated and high in concentration. The local inflated concentration reaches 100%, and the maximum inflatable size is 2500×3000mm.

• The suction cup is equipped with an anti-connection valve to reduce the consumption of air source and ensure that the glass is firmly absorbed and does not sag.

• There are anti-glass sagging and automatic film picking functions when closing the film inside.

How to Fill Gas On Line?

After the first piece of glass enters the pressing section, the front plate sucker works, but the pressing plate does not open. After the second piece of glass is installed with the aluminum spacer , the foot switch starts the glass transmission, and the pressing plate opens, the side inflatable plate and the lower When the inflatable plate stretches out and the second piece of glass enters the plate pressure, it will synchronize with the sealing baffle. After the glass stops, it will be lifted down and there will be a signal. Close to the inflation position and start inflation. After the inflation time is reached, continue to inflate while pressing in place, the inflation will be closed, and the pressure plate will be opened after the pressure is maintained, and the inflation and fusion sheeting is completed.

Note: When inflating, the bottom, left and right sides of the glass are all sealed to reduce argon consumption.

TECHNICAL SPECIFICATION

Max. Glass Size | 2500*3500mm | mm |

Min.Glass Size | 500×300 | mm |

Min.Glass Size for gas filling | 600×300 | mm |

Thickness of insulated glass | 12-60 | mm |

Thickness of glass sheet | 3~12 | mm |

Washing Speed | 2~12 | m/min |

Air Pressure | 5~8 | Kgf/cm2 |

Hydraulic Pressure | 5~10 | MPa |

Total Power | 45 | KW |

Machine Size | 2418 *3000*3600 | mm |

STANDARD ACCESSORIES

PLC | SIEMENS |

Frequency converter | SIEMENS |

Servo Motor | SIEMENS |

Touch Screen | SIEMENS |

Photoelectric switch | Omron |

Low-voltage electrical appliances | Schneider |

Cylinder | SMC |

Negative pressure gauge | Festo |

Solenoid valve | SMC |

Transfer Belt | China Brand |

Guide | CSK |

Roller screw | Taiwan Brand |