2000MM CNC ALUMINIUM ROUTER FOR DOORS WINDOWS

MAIN FEATURES

1. 2000mm CNC aluminium router machine, also called CNC milling machine, is suitable for milling and drilling of lock hole, drain holes, and hardware installation holes of aluminum door and window profiles. The maximum machining length of its milling cutter from left to right is 2000mm. (800mm, 1200mm and 1500mm are also available)

2. Pneumatic swing angle function. The workbench can automatically flip three angles to realize the processing of three sides of aluminum profile.

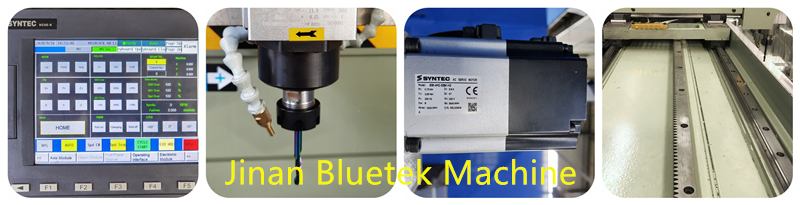

3. The drive motors on the 3 axes all adopt servo motors, which are stable in operation, accurate in positioning and long in service life.

4. Adopt Taiwan's SYNTEC control system to store all the hole types processed by doors and windows. You only need to select graphics and enter dimensions such as side length, width or radius to process. The operation is simple and fast.

5. X-axis movement adopts rack and pinion and precision guide rail, which has fast running speed, very stable and high processing precision.

6. The machine body of CNC aluminium router adopts rigid design and aging treatment to ensure the stability of the machine; the low-voltage electrical appliances adopt Schneider brand, and the pneumatic components adopt Taiwan Airtac.

TECHNICAL SPECIFICATION

| Model | LSKX-CNC-2000 | LSKX-CNC-1200 | LSKX-CNC-800 |

X-Axle Range | 2000mm | 1200mm | 800mm |

Y-Axle Range | 300mm | 300mm | 300mm |

Z-Axle Range | 300mm | 300mm | 300mm |

| X-Axle Speed | 90M/min | 30M/min | 30M/min |

| X-Axle Speed | 60M/min | 20M/min | 20M/min |

| X-Axle Speed | 60M/min | 20M/min | 20M/min |

| Spindle Rotary Speed | 18000 rpm | 18000 rpm | 18000 rpm |

| Spindle Power | 3.5KW | 3.5KW | 3.5KW |

| Total Power | 7.5 KW | 5 KW | 5 KW |

| Air Pressure | 0.5 ~0.8MPa | 0.5 ~0.8MPa | 0.5 ~0.8MPa |

| Workbench Angle | -90° ,0° ,+90° | -90° ,0° ,+90° | -90° ,0° ,+90° |

| Size | 3000x1600x1800mm | 1800x1600x1700mm | 1000x1600x1700mm |

| Weight | 1300 KG | 800KG | 600KG |

PROCESSING EFFECT OF CNC ALUMINIUM ROUTER MACHINE

PACKING AND DELIVERY

CNC aluminium router will undergo quality inspection and test machines before shipment, and then acceptance and packaging. We ensure that customers do not need to make additional adjustments after receiving the machine, and can start production after turning on the power and air supply.

It is packaged with waterproof plastic film;

Lubricating oil is sprayed on the guide rails, sliding blocks and saw cuts to prevent rusting during shipping;

The two saw heads are fixed with angle irons to prevent movement.

The outer packaging is a fumigation-free wooden case (LCL)

Tray and steel wire to fixe body (FCL)