TECHNICAL SPECIFICATION

Model | SZA400 |

Total Power | 11.0 KW |

Input Power | 380V 50Hz 3Phase |

Air Consumption | 80 L/min |

Air Pressure | 0.6-0.8 MPa |

Motor Power | 3.0 KW * 2 |

Motor Speed | 2840 r/min |

Diameter of Blades | Φ350mm×φ30mm |

Diameter of main shaft | Φ30 mm |

Milling Depth | Max. 120 mm |

Milling Height | Max. 200 mm |

Workbench Width | 595 mm |

Overall Dimension | 2880*1880*2160 mm |

Net Weight | 1900 KGS |

MAIN FEATURES

• Suitable for milling the end faces of the stiles and reinforced stiles of aluminum alloy profiles. The five-axis controls the upper, lower, front and rear positions of the two spindle motors.

• Intelligently adjust the tool position. The tool can be adjusted up and down, front and back, and can process different structures such as step surfaces, rectangular grooves and tenons.

• The servo motor drive is more stable and efficient, and the five-axis 4 tools can run more efficiently. The clamping cylinder has four guide columns to ensure that the profile does not run or press.

• Super powerful functions, milling multiple profiles at a time, and can achieve high efficiency in reciprocating milling.

• Scanning code processing can be realized, and 5-axis 4-tool reciprocating milling is more efficient.

• The absolute value of the bus makes the system more stable and the milling accuracy more accurate.

• The CNC adjustment tool can be adjusted up and down, front and back to adapt to the processing of different shapes and sizes.

• The tool diameter is large, and the cutting of the reinforced rib part of the stile can be completed at one time.

• Ability to store a large number of profile programs and retrieve them with one click, convenient and fast.

DETAILS OF CNC 5 AXIS ALUMINUM WINDOW ENDFACE MILLING MACHINE

ABOUT BLUETEK

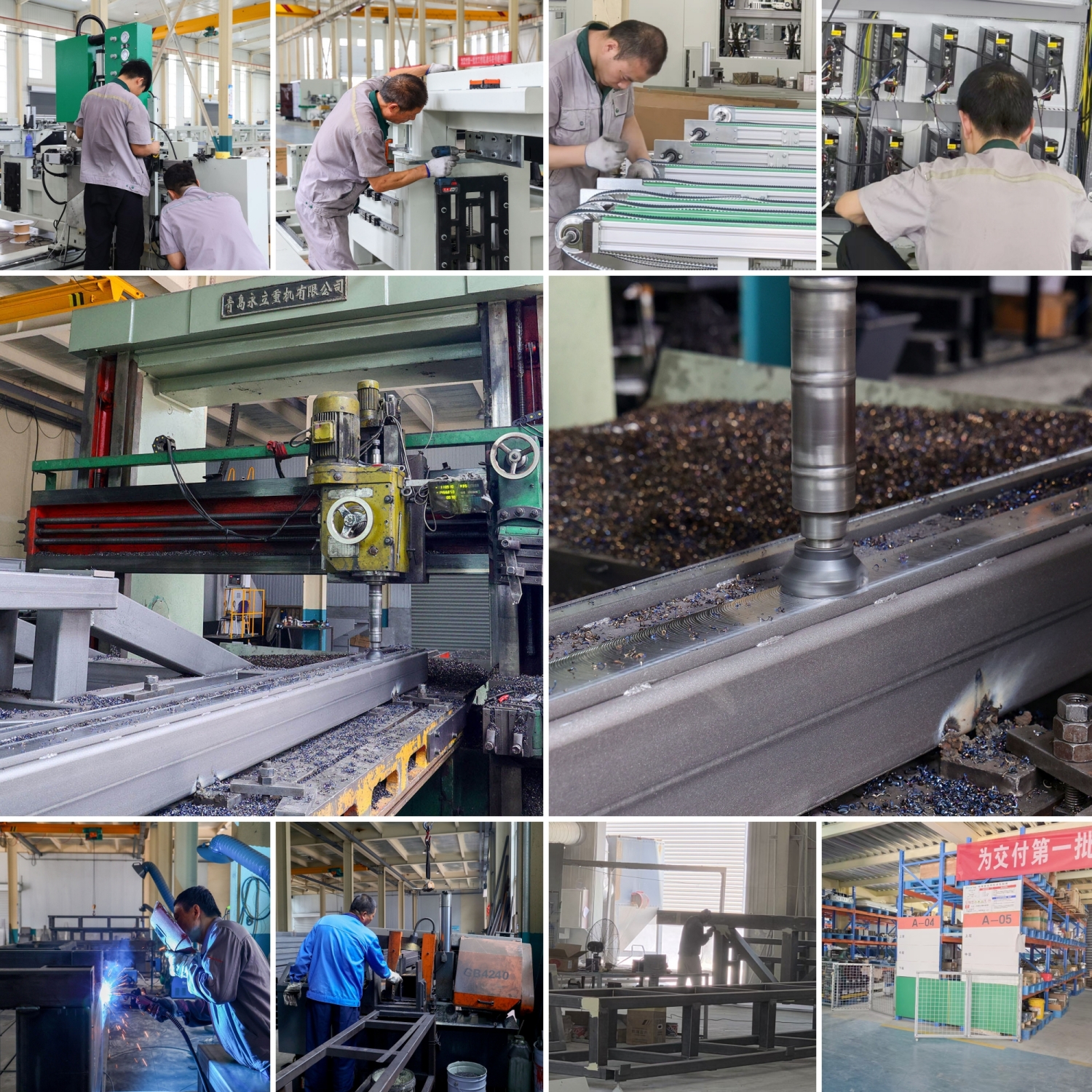

BLUETEK is located in Jinan, Shandong, and have been specialized in mid-to-high-end aluminum door and window manufacturing machines, aluminum curtain wall manufacturing machines, PVC door and window manufacturing machines, as well as industrial aluminum processing equipment and solutions for 20 years.

Our company currently has three modern workshops with a total area of 18,000 square meters, with its own machining, sheet metal processing, and spraying. The total number of employees is more than 100, with a research and development team of more than a dozen people.

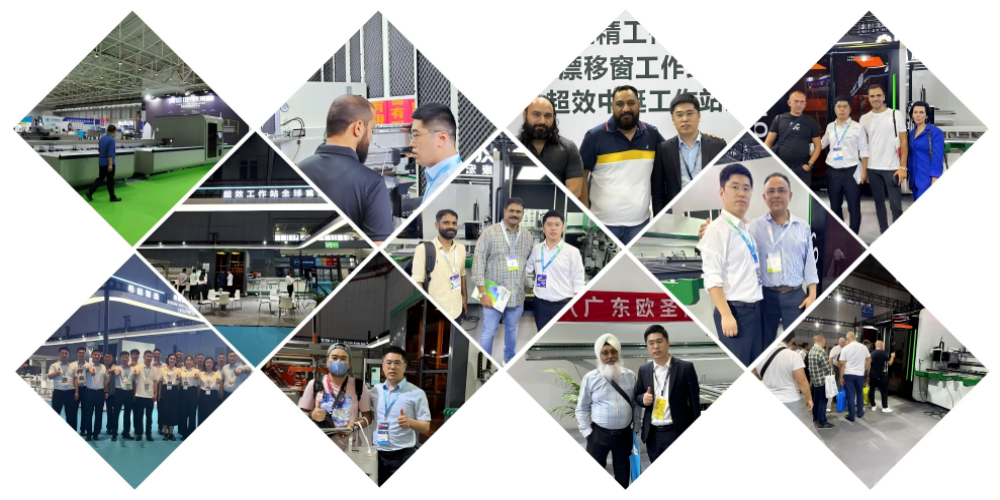

Professional exhibitions at home and abroad

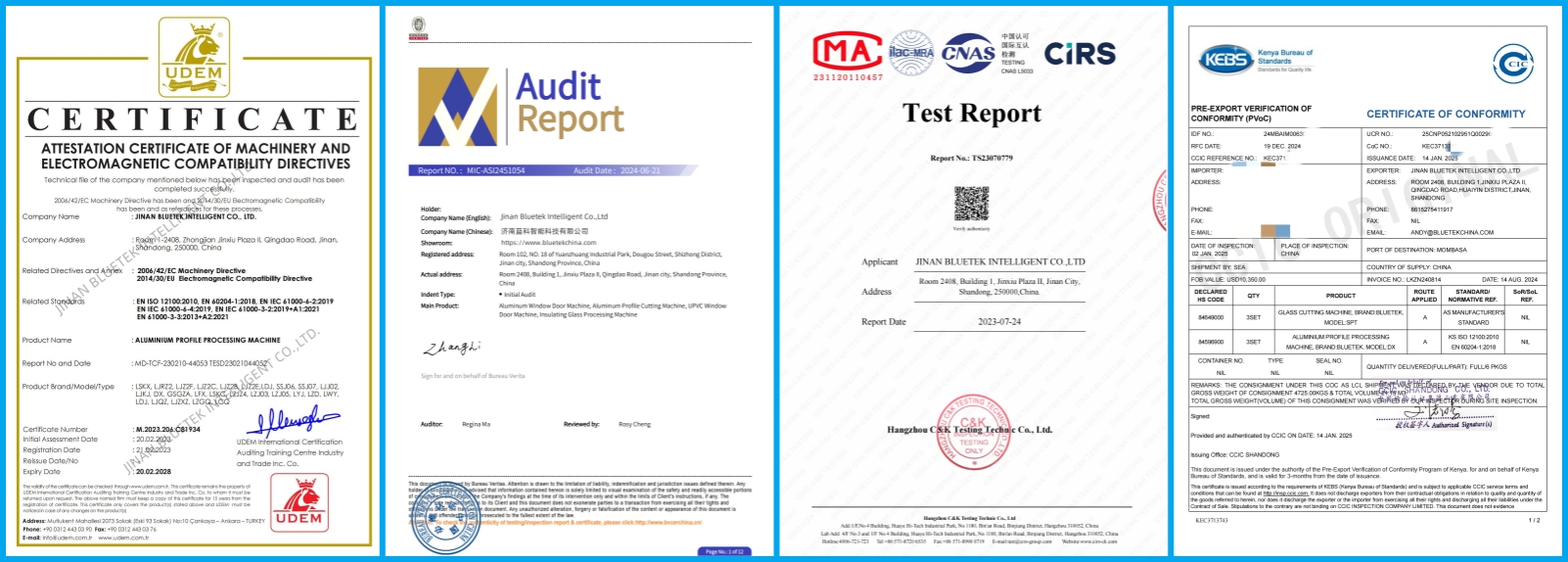

Our products have passed European CE certification, BV certification, CNAS test report, etc., ensuring the safety of the products.

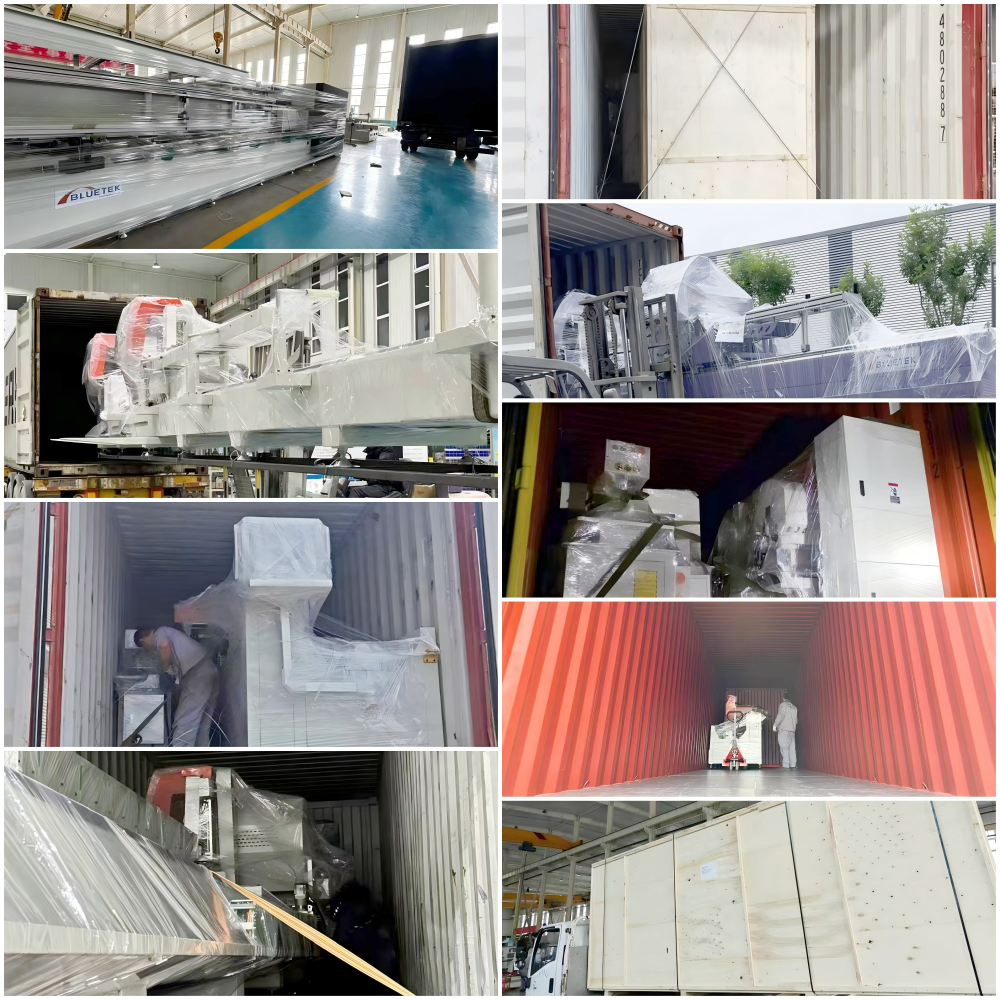

Transportation mode: By sea, rail, land

Loading mode: FCL, LCL

Packing: plastic waterproof film + plywood box

BEST PARTNER:

SZA620 ALUMINUM WINDOW CNC MACHINING CENTER + CNC 5 AXIS ALUMINUM WINDOW ENDFACE MILLING MACHINE = 200+ SQUARE METERS / 8 HOURS