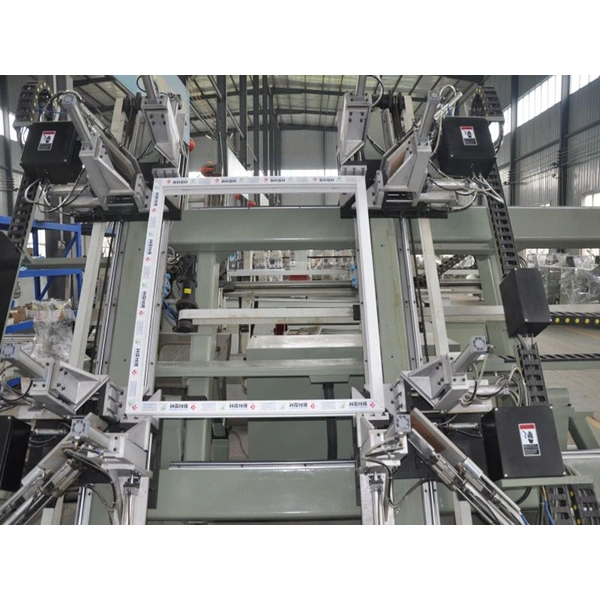

CNC FOUR HEAD WELDING MACHINE FOR PVC DOOR WINDOW

UPVC WINDOW VERTICAL FOUR CORNER WELDING MACHINE CNC

The CNC PVC windows four head welding machine adopts a vertical structure, and the heating plate and the positioning plate are fed horizontally. It can complete the welding of a window frame at one time, and the efficiency is high.

The four machine heads are automatically positioned, fed and welded, and the work intensity is reduced.

Control system and temperature controllers of CNC four head welding machine are both from Japan Omron, is more stable and durable. All parameters can be set through the touch screen, the operation interface is simple and friendly.

MAIN FEATURES

• Fully automatic CNC four head welding machine, which can complete the welding of four corners of a window frame at a time.

• Use Omron control system, only need to input door and window size, four machine heads are automatically positioned, reducing labor intensity.

• Using ball screw motion pair, high welding accuracy.

• The two pressure clamps of each head are fed simultaneously, and the welding angle is stronger.

TECHNICAL SPECIFICATION

| Model | SHP4A-CNC-3000x1800x120 |

| Name | CNC Four Head Welding Machine |

| Power Volatge | 220V 50Hz |

| Air Pressure | 0.6~0.8MPa |

| Air Consumption | 80L /min |

| Welding Height | 120mm |

| Welding Width | 25~160mm |

| Welding Range | 400x400mm ~ 1800x3000mm |

| Total Power | 9KW |

| Machine Dimension | 5000x2000x1860mm |

| Weight | 3000 KGS |

PACKING AND SHIPPING OF FOUR HEAD WELDING MACHINE

If UPVC windows and doors making machine is shipped by LCL by sea, each machine will be packed in a fumigation-free wooden box, which meets the customs and environmental department requirements of the recipient country.

If UPVC windows and doors making machine is shipped by FCL by sea, the bottom of the machine will be fixed on the pallet, and the machine will be fixed in the container with steel wire to ensure that the machine will not shake and be damaged.