MAIN FEATURES

1. High-end PVC window double head welding machine, double-sides seamless welding machine is the most important machine for the production of plastic doors and windows. It has a direct impact on the appearance, strength, and quality of the window corners.

2. Seamless welding means that during the welding process, the upper plane and the lower plane have a sharp knife to cut off the molten welding slag, leaving a very thin seam, which is very beautiful. The upper plane and the lower plane of the window corner do not need to be cleaned with a corner seam cleaner.

3. Need to clean the outer corner seam and inner corner seam, reducing the process steps, simple corner cleaning machine or manual tools can be completed.

4. The left welding head and the right welding head can work independently or in linkage. The left head of the double head welding machine is fixed, and the right head can move and weld doors and windows of different sizes, and can weld at any angle, suitable for arc windows.

5. The precision square and round guide rails are used to ensure the precision and stability of the machine movement and long service life.

6. The double head welding machine can weld color co-extruded profiles, color coated profiles and ordinary white PVC profiles. The welding effect is beautiful and the strength is high. It is more and more popular with customers at home and abroad.

TECHNICAL SPECIFICATION

| Product Name | PVC Window Double Head Welding Machine for Seamless Welding |

| Brand | BLUETEK |

| Model | WFH-2 |

| Power Supply | Customize |

Input Power | 2.5 KW |

Air Pressure | 0.6~0.8 MPa |

Welding Height | 120mm |

Welding Width | 20 ~120mm |

Welding Length | 450~3500mm |

Weight | 1500 KG |

Overall Dimension | 5500*1200*2000mm |

DETAILED PICTURES

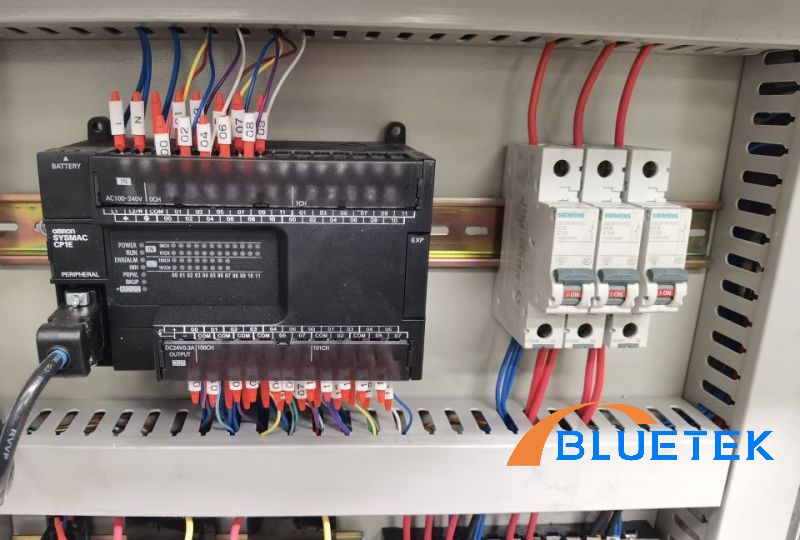

Control panel and buttons

PLC is from Japan Omron, controls the working of the PVC double head welding machine.

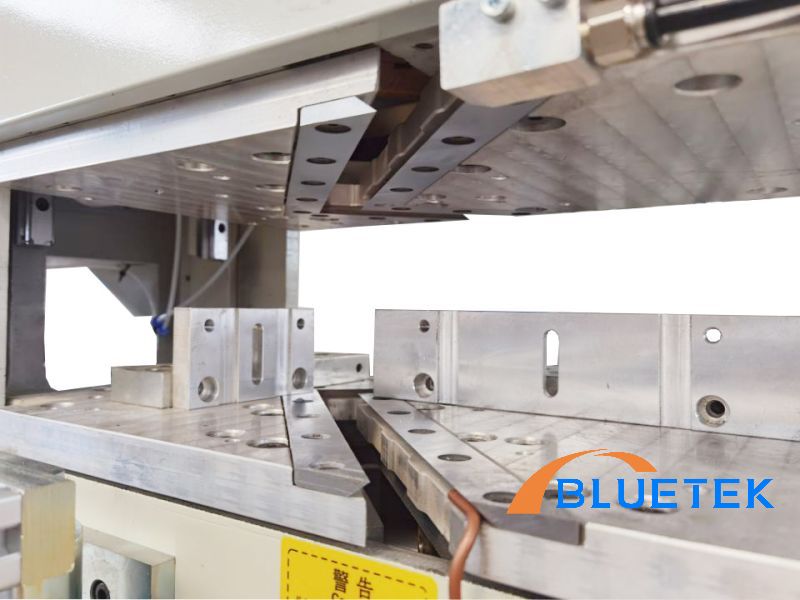

There are total 8 pieces of cutters on each welding head, replacement is very simple.