Are you tired of manually fabricating aluminum windows and doors? Look no further than our top-of-the-line aluminum window working machine!

Our machine is specifically designed to streamline the fabrication process of aluminum windows and doors, saving you both time and energy. With its advanced automation technology, you can create high-quality aluminum windows with precision and efficiency.

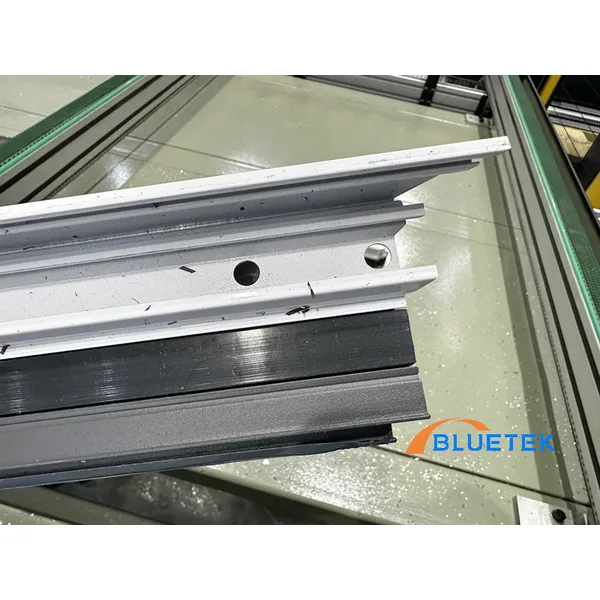

The aluminum window working machine features a variety of tools that are tailored to meet your specific needs. From cutting and drilling to milling and punching, our machine can handle it all. Its robust construction ensures durability, and its user-friendly interface makes it easy to operate.

By investing in our aluminum window working machine, you can increase your productivity and take your business to the next level. Say goodbye to the long hours and labor-intensive processes of manual fabrication and hello to a new era of streamlined manufacturing.

Upgrade your fabrication process today with our aluminum window working machine. Contact us now to learn more about our product and how it can benefit your business.

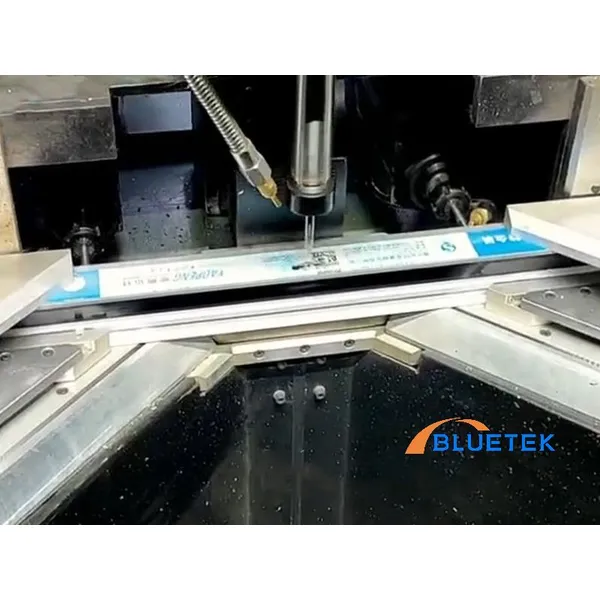

The aluminum window working machine adopts Schneider industrial control system and bus servo drive control unit, integrating ERP door and window software. Realize 45-degree angle cutting, horizontal drilling, vertical milling, and laser scribing.

Circular working, the machine - aluminum window working machine composed of feeding section, processing section and unloading section. Using 15 CNC axes and bus servo control unit axes, frequency conversion, multi-stage compaction and material support are respectively realized by CNA communication, frequency converter, driver bus, and PLC control program, and the data transmission is stable and fast.

The system supports various mainstream ERP optimization software. After simple system settings, cutting and milling operations can be performed according to the optimized data.

Milling & Drilling of Aluminum Window Working Machinery: Corner connector holes, dowel holes, glue injection holes, drainage holes, key holes, window mullion marking, drive chamfering, etc.

TECHNICAL PARAMETERS OF SZA600 ALUMINUM WINDOW WORKING MACHINE

| Model | SZA600 |

| Name | Aluminum Window Working Machine CNC |

| Power Supply | 380V 50Hz |

| Input Power | 15KW |

| Air Pressure | 0.6 ~0.8 MPa |

| Air Consumption | 200L /min |

| Environment Temperature | -5℃ ~ 60℃ ( LCD screen : 0℃ ~60℃) |

| Spindle Motor Rotating Speed | 2850r/min |

| Saw Blade | 550mm*4.4mm*30mm*120T |

| Cutting Angles | 45° * 2 |

| Cutting Range | 150*150mm |

| Cutting Mode | Up Cutting |

| Cutting Length Accuracy | ≤0.2mm |

| Verticality | ≤0.1mm |

| Cutting Angle Accuracy | 4' ~6' |

| Loading Profile Length | 2000mm ~6500mm |

| Cutting Length Range | 300mm~6000mm |

| Loading Profile Quantity | 7 PCS |

| Manipulator Feeding Stroke | 6500mm |

| Manipulator Discharging Stroke | 1000mm |

| C Axis Clamping Range | 300~5000mm |

| Manipulator Feed Speed With Profiles | 60~100M /min |

| Manipulator Discharge With Profiles | 60~100M /min |

| Saw Blade Cutting Speed | 20~50M/min |

| Overall Dimension | 14000*5000*2600mm |

| Weight | Around 6000 KGS |

CONFIGURATION LIST OF SZA600 ALUMINUM WINDOW WORKING MACHINE

| Control System | Schneider, France | 1 Set |

| Servo Driver | Schneider, France | 15 Set |

| Servo Motor | Schneider, France | 15 Set |

| Industrial Display | Philips, France | 1 Set |

| Cables | LAPP, Germany | 240 M |

| AC Contactor | Schneider, France | 8 PCS |

| Low Voltage Circuit Breaker | Schneider, France | 8 PCS |

| Phase Sequence Protector | Schneider, France | 1 PC |

| Transformer | LAPP, Germany | 1 PC |

| Switch Buttons | Schneider, France | 20 PCS |

| Proximity Switch | Contrinex, Switzerland | 20 PCS |

| Hall Switches | ALIF , Taiwan China | 10 PCS |

| Limit Switch | Schneider, France | 4 PCS |

| Precision Ball Screw | PHI , Taiwan China | 2 M |

| Linear Guides | SBC, South Korea | 10 M |

| Rectangular Guide Rail | PHI , Taiwan China | 20 M |

| Rectangular Slider | PHI , Taiwan China | 30 PCS |

| Spindle Motor | SHENYI, China Top Brand | 2 SET |

| Saw Blade | WAGEN , Japan | 2 PCS |

| Air Cylinder | AirTAC, Taiwan China | 28 PCS |

| Solenoid Valve | AirTAC, Taiwan China | 8 PCS |

| Speed Control Valve | AirTAC, Taiwan China | 30 PCS |